Choosing Between Embroidery & Screen Printing as a Branding Option

Branding is the art of creating a distinct and memorable identity for a business. It's an important aspect of a marketing strategy and plays a significant role in how customers perceive a company. Two popular branding options, embroidery and screen printing, offer unique benefits that can help enhance a company’s presence.

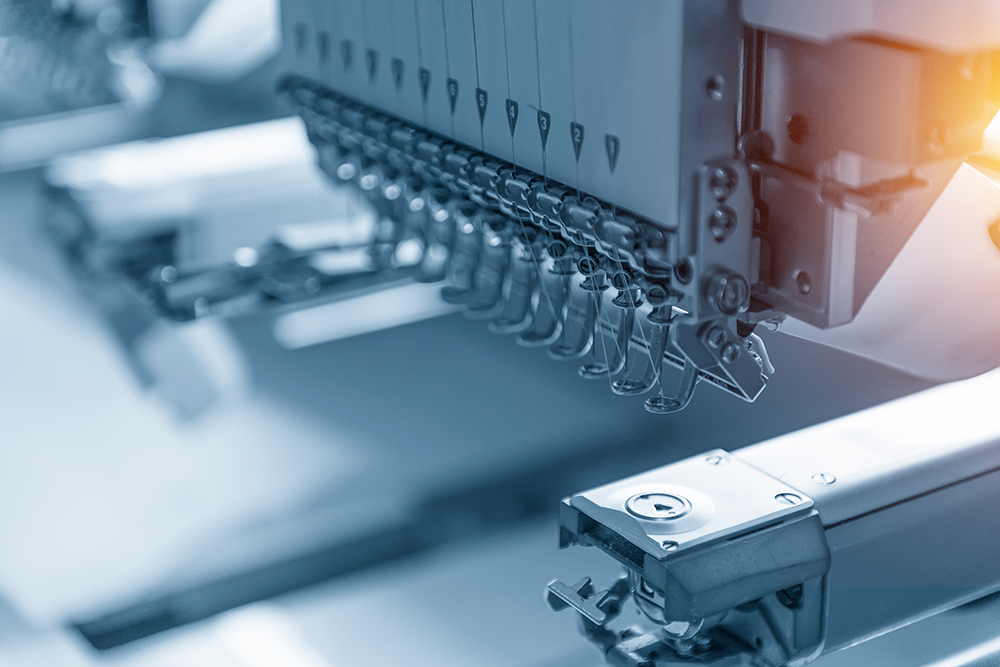

Embroidery as a Branding Option

Embroidery, as a branding option, offers a unique and timeless way to adorn apparel and products with intricately stitched designs. The craft of decorating fabric using a needle and thread has a rich history spanning centuries, and its application in branding brings a touch of elegance and sophistication to any item it adorns.

Unlike digital printing or the screen printing method, which involves passing ink through a mesh screen onto a substrate, embroidery adds texture and depth to the final product, creating a tactile and visually appealing representation of the printed design or logo. While screen print and silk screen printing can produce vibrant, multi-coloured images quickly and efficiently, especially when using a specialised fabric printer or a printing board within a metal or wooden frame, embroidery leverages silk thread for its lustrous appearance and durability, enhancing the quality and luxurious feel of the work.

The attention to detail when option for embroidery ensures that the final item exudes a sense of craftsmanship and artistry, setting it apart with a sophisticated touch that resonates with the brand's identity and values. In contrast to the broad capabilities of printing companies that offer screen printing for large-scale production, embroidery offers a bespoke, artisanal approach to branding, making each piece a unique representation of the brand.

Benefits of Embroidery for Branding

Durability:

Embroidery is resilient against fading and provides a three-dimensional texture that endures regular washing and wear. The incorporation of silk thread ensures that the colours and structure of the embroidered design remain intact over time, offering longevity that printed alternatives might not match.

Perceived Quality:

The satin stitch and even the more complex running stitch imbue a premium feel, elevating the perceived value of the product. When embroidery is executed with silk thread and in more than one colour, it showcases a level of detail and richness that can significantly enhance brand recognition and value.

Versatility:

From caps to corporate wear, embroidery fits a range of materials. An embroidery machine efficiently handles complex designs with ease, allowing for the integration of multiple colours and intricate patterns. This adaptability makes it possible to reproduce a brand's logo with high fidelity across various textiles, ensuring consistent branding across all merchandise.

A Step by Step Guide to Embroidery

Step 1 - Gather Your Materials:

To begin embroidering, you will need an embroidery hoop, which consists of two parts and helps keep the fabric taut, small and sharp scissors, and your choice of fabric.

Step 2 - Select Your Design:

Choose the design you want to embroider. This can be a pre-printed pattern on the fabric or a design you create yourself.

Step 3 - Prepare the Fabric:

Place the fabric in the embroidery hoop and tighten the screw to secure it in place. This ensures that the fabric remains taut and makes stitching easier.

Step 4 - Thread the Needle:

Cut a piece of embroidery floss to a manageable length (usually around 18 inches) and separate out one to three threads, depending on the thickness you desire. Thread the needle and tie a knot at the end.

Step 5 - Start Stitching:

There are various stitches to explore in embroidery, such as the running stitch, satin stitch, split stitch, and more. Each stitch creates a different effect and texture, so experiment with different techniques to bring your design to life.

Step 6 - Finishing Touches:

Once you've completed your embroidered design, carefully remove the fabric from the hoop and trim any excess threads. You can also gently wash the fabric to remove any marks left by the hoop.

Screen Printing as a Branding Option

Screen printing, a dynamic option for branding, leverages a silk screening technique where ink is pressed through a mesh screen onto a substrate, achieving vibrant, full-colour results on diverse materials such as textiles, plastics, and metals.

The screen printing method excels in producing large volumes of custom apparel and promotional items efficiently, offering a cost-effective way for businesses to enhance their brand presence. The precision of screen printing ensures that even the most intricate designs are reproduced with clarity, significantly boosting brand recognition.

When compared to embroidery's textured and durable appeal, screen printing stands out for its ability to create bold, colourful imagery that captures attention. Understanding the advantages of both screen printing and embroidery allows companies to choose a branding method that best fits their aesthetic, budget, and industry needs, ensuring their message reaches the intended audience with maximum impact.

Benefits of Screen Printing for Branding

Scalability:

The screen printing method, particularly when using an automatic rotary carousel printer, is perfect for large orders due to its quick setup and production speed.

Vibrancy:

Using specialised fabric printers, screen printed images boast vibrant colours, even on darker fabrics. The screen printing technique ensures colours pop thanks to the use of very bright light during exposure.

Cost-Effectiveness:

For large quantities, this method can be more economical. Unlike digital printing, screen printing's cost per unit decreases as the quantity increases.

A Step By Step Guide to Screen Printing

Step 1 - Design Preparation:

Begin with creating or selecting the desired design for screen printing. This can be achieved through digital printing, design software or hand-drawn artwork.

Step 2 - Screen Preparation:

A fine mesh fabric, usually made of polyester, is stretched tightly over a frame made of metal or wood to create the screen. The screen is then coated with a light-sensitive emulsion, which is dried in a dark environment.

Step 3 - Exposure:

The designed image is printed on a transparent acetate film and placed on top of the coated screen. The screen is exposed to a very bright light, causing the emulsion to harden except where the design blocks the light.

Step 4 - Washing:

The unexposed emulsion is washed away, leaving a stencil of the design on the screen. This process creates open areas through which the ink will pass during printing.

Step 5 - Printing Setup:

The prepared screen is mounted on a screen printing press, and the printing board is placed underneath. The fabric or material to be printed is laid flat on the the printing press board.

Step 6 - Ink Application:

Ink is poured onto the top side of same stencil on the screen, and a squeegee is used to spread the ink across the screen. The ink is forced through the open areas of the stencil onto the material below, creating the printed image.

Step 7 - Drying and Curing:

Once the image is transferred, the material is passed through a dryer or exposed to heat to cure the ink, ensuring a lasting bond with the fabric.

Step 8 - Repeat and Align:

For multi-coloured designs, each colour requires a separate screen and printing process. Precise alignment is crucial to ensure that each colour is layered accurately over the previous ones.

Factors to Consider

When choosing between embroidery and the screen printing technique, consider factors like fabric type, design intricacy, and overall budget. Screen printing uses a transparent acetate film for transferring intricate designs onto the fabric, ideal for detailed graphics and fabric printing. This method is great for printing images with precision. Embroidery, enhanced by the long and short stitch, suits straightforward, bold logos, offering a textured, high-quality appearance. Each has its advantages, with screen printing providing vibrant, clear images and embroidery offering a premium, tactile feel.

Case Studies

Rather than companies, let's look at the products themselves. Time and again, we've seen screen-printed t-shirts surge in popularity due to their relaxed style and bold messaging, while embroidered polo shirts maintain a stronghold in the corporate and hospitality sectors due to their sophisticated appeal.

Ultimate Tips and Tricks for Screen Printing & More

For durability and a classic look, embroidery may be the way to go. On the contrary, if you prefer bold and large designs on casual wear, the silkscreen method screen printing, or simply put, screen printing method, could be your best choice.

Consider a silk screening process using a fine mesh screen for detailed artwork, where a rubber blade attached to a screen printer spreads ink over the screen, allowing for the application of multiple colours.

This technique is ideal for achieving vibrant, eye-catching designs on a variety of fabrics. Alternatively, opt for the sturdy satin stitch of embroidery for text-based logos, where the tactile nature and depth of the stitch add a distinctive premium feel to the design.

Elevating Your Brand's Visibility and Perception with Silk Screen Printing & Hand Embroidery

Your brand's visibility and perception largely depend on the quality and appropriateness of your chosen branding option. Whether you choose the silk screen printing method for its vibrancy and ability to produce bold, clear screen printed name designs, ensure it aligns with your company's aesthetic and values.

Embracing Embroidery: Sophisticated Appeal for Your Brand's Messaging

Embrace the branding journey, examine samples from digital printing companies, and inquire about the screen printing process, including the use of automatic presses, light reactive emulsion, and the intricacies of applying puff inks or glittery inks on polyester fabrics and other materials at your local printer. Delve into the detailed work that goes into using an embroidery machine, exploring how silk thread and techniques like the back stitch add a unique texture.

By understanding the strengths of each technique, from the vibrant versatility of screen printing, which employs a mesh screen and CMYK style dots for printed designs in multiple colours and can include special effects using acetate sheets for precise designs in liquid form, to the timeless elegance and fine art of embroidery that offers a sophisticated appeal with its depth and tactile quality, you'll be better positioned to decide. Whether it's the bold statement of screen printing and silk screen printing, capable of creating dynamic visuals with a range of inks on various substrates, or the intricate, luxurious feel of embroidery that best aligns with your brand's messaging, each method offers distinct advantages for projecting your brand into the public eye with confidence.

Conclusion

Whatever you choose, whether it's a clear printed image through the basic technique of screen printing or a finely executed design with silk thread in embroidery, these branding methods will carry your company's identity into the public eye with confidence. Screen printing, also known as silk screen printing, uses a silk mesh screen to transfer ink onto a substrate, offering a distinct advantage in versatility and durability over digital printing methods.

The screen printing process allows for bold, vibrant colours and is ideal for high-volume orders, ensuring your brand's visuals are reproduced with clarity and precision.

Leave a comment